Making Your Own Black Powder

Weapons, in general, are an important part of survival. For the last few hundred years, these have mainly been in the form of firearms, which have replaced pretty much all other weapons for everything from self-defense to hunting. Yet, in a long-term survival situation, keeping those firearms operable and finding enough ammunition for them may become a great challenge.

Of course, many of us have ammunition stockpiled for such an event, but even that may not be enough. No matter how big your stockpile is, it will eventually run out. Between hunting for food and defending yourself, you might end up going through more ammunition than you expect – especially rifle ammunition. So what do you do when your stores run low?

If you’ve got a reloading rig and put in a good stockpile of supplies, you’ll be able to keep going longer. But once again, your stocks will be limited and will eventually run short. At some point in time, we’ll all have to have an alternative – perhaps other types of weapons or making our own ammo.

Making your own ammo isn’t as far-fetched an idea as it may seem. Back in the early days of our country, many people made their own. Of course, rifles were simpler back then so it was easier for them to make it; but, the basic idea of making lead shot and black powder can readily be adapted for reloading modern ammunition as long as we save the cartridge cases for reuse.

How to Make Black Powder

There are a variety of black powder recipes around. These all vary slightly in the mix and proportion of ingredients, but the basic mix (by weight) is:

- 75% Saltpeter

- 15% Charcoal

- 10% Sulfur

Please note that this is a fairly dangerous operation, so you’ll need to do it outdoors where you have good ventilation and access to water to put out a fire if necessary. The black powder won’t explode if it isn’t in a sealed container, but it could catch fire and burn.

In a post-disaster world, you’d want to do this project in the wintertime as you would need a means of chilling the alcohol and the raw black powder mixture. Without refrigeration, you’ll either need snow, ice, or cold outside temperatures to make it possible to make your gunpowder.

For the charcoal, you’ll need to use a wood that provides a fine charcoal when ground such as willow, birch, fir, oak, or spruce. To make the charcoal, place wood chips in a metal container with a small hole in the lid for gasses to escape. Set this container in a fire and allow it to heat to cause steam to escape from the wood. Light the chips in the container on fire and place the lid on.

This will cause the hydrocarbons to burn off from the wood – drying it and turning it into charcoal. Once the fire burns out, allow the container to cool and open it to find your charcoal.

1. All three of the ingredients should be finely ground – either in a grain mill or with a pestle & mortar. Sift the ground ingredients to ensure that you have removed any large pieces.

2. Chill 2 ½ cups of isopropyl or denatured alcohol for every 100 grams of ingredients you are going to use. Obviously, this means that you are going to have to have a source of alcohol to use. While isopropyl alcohol is ideal, other forms of grain or wood alcohol can be used. The easiest way to make alcohol in a post-disaster world would probably be from cornmeal.

3. The saltpeter then needs to be made into a solution by dissolving it at a ratio of 100 grams for every ½ cup of clean water. Bring to a boil so that you get a supersaturated solution. Add a small additional quantity of water, if needed, to get all the saltpeter to dissolve.

4. Mix the charcoal and sulfur together, then mix them into the boiling saltpeter mixture. Stir until all the ingredients are fully dissolved.

5. Now, mix the boiling hot mixture with the chilled alcohol, pouring the hot mixture into the alcohol. Chill this new mix as quickly as possible, bringing it down to 32°F (0°C). Please note that it will not freeze at this temperature due to the presence of alcohol, so you’ll need a means of checking the temperature.

6. As it freezes, the solids should start settling out of the liquid mixture. Filter the mixture through a cheesecloth or an old t-shirt to separate out these solids. The liquid can be disposed of.

7. Spread the solid mixture out on paper and allow to sit in the sun to dry. While it is still damp, press it through a sieve or screen to remove any lumps, then spread it out on paper again to finish drying.

8. Run the dry mixture through a sieve several more times to remove any large chunks. A good way of doing this is to make a frame with fine wire mesh screening stretched over it. A roller (such as a rolling pin) can then be used to push the mixture through the screen, breaking it up and grinding it back into a fine powder.

This fully-dried, finely-ground mixture is black powder and can be used for reloading cartridges for your firearms. Keep in mind that it will not be as powerful as the modern “smokeless powder” that you are accustomed to using, so the ballistics will be different. Expect more drop from your bullets as they go downrange. You may want to do some test firing in order to develop your own ballistic data.

A Word About Saltpeter

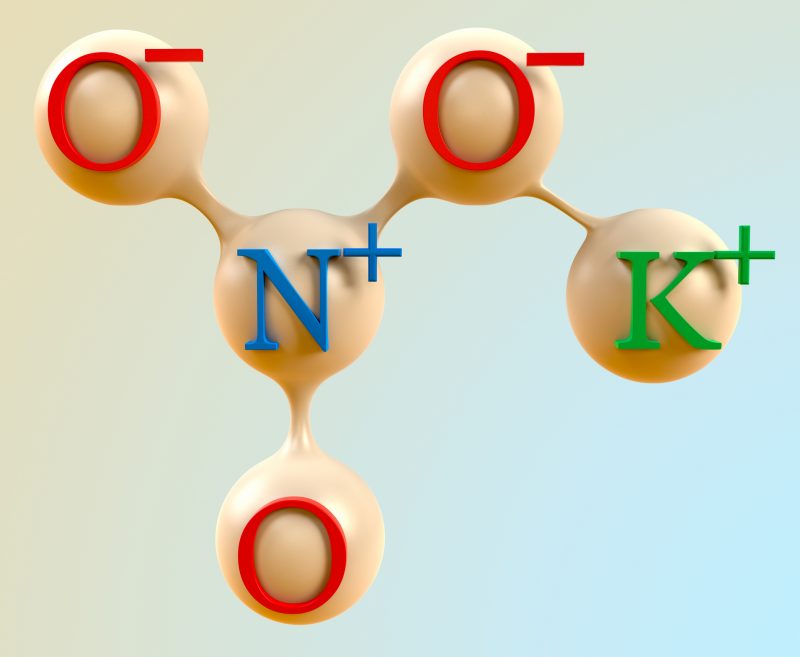

The key ingredient in the making of black powder is obviously saltpeter, which is potassium nitrate. In times when horses were the common means of transportation, it could be found as white crystals on the sides of the stalls in barns. People then started making it intentionally by creating a bed of animal feces and straw and keeping it moist with urine.

This causes the normal decomposition of the organic matter, which is essential for the saltpeter to form. Once the mixture is broken down (after several months), the top couple of inches of now decomposed feces, without the straw, is moved to another area so that the saltpeter crystals can form. These are then harvested off and leeched out with water before being allowed to crystallize once again.

Please note that this is a lengthy process that can take seven months to a year depending on the temperature. So, if you are going to make your own saltpeter to make your own black powder, you must start working well in advance.

A Word About Molding Bullets

Modern bullets are generally “jacketed” with a copper skin. The jacketing is formed and then molten lead poured into it to fill the bullet and add weight. In times past, there was no jacketing and instead merely a lead slug. However, there is no reason why we couldn’t go back to using lead bullets in an emergency. Much ammo reloading at home is done with lead bullets.

The question then becomes: where do we get lead from? It’s actually quite easy. The lead that is used in the ammunition you and I buy at the store isn’t lead that has been smelted down from lead ore taken from the ground, but rather recycled lead that goes through a process known as secondary smelting to make it usable.

You and I can do this as well. The two easiest sources of lead we can find are the weights used for balancing car tires and the lead in car batteries. Of the two, wheel weights are the easiest to work with as they merely have to be melted down and poured into a mold. The lead in car batteries, on the other hand, has to be melted and separated from other materials; hence the term “secondary smelting.”

Essentially, this process consists of taking the battery apart and rinsing all the internal components thoroughly with water to remove the acid. Then, the metal plates (which will contain some plastic and other metals as well as the broken-up lead plates) at the bottom of the battery are melted down. As lead is heavy, it will settle to the bottom and the other materials can be skimmed off. The lead in the bottom of the melting pot will be pure lead, which can be used to mold bullets.